.gtranslate_wrapper

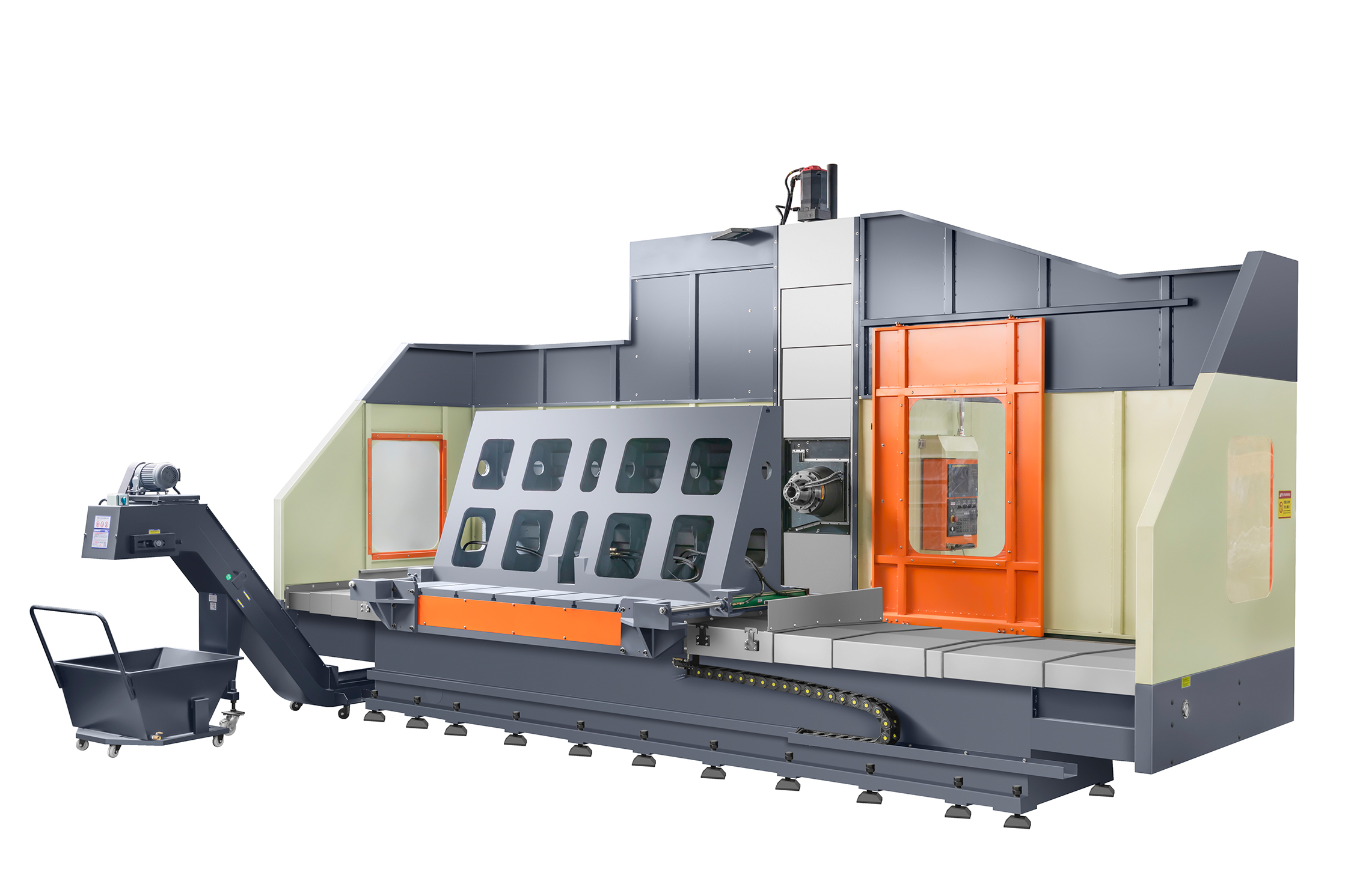

Gantry Milling & Boring

Precision Redefined

OUR Machine

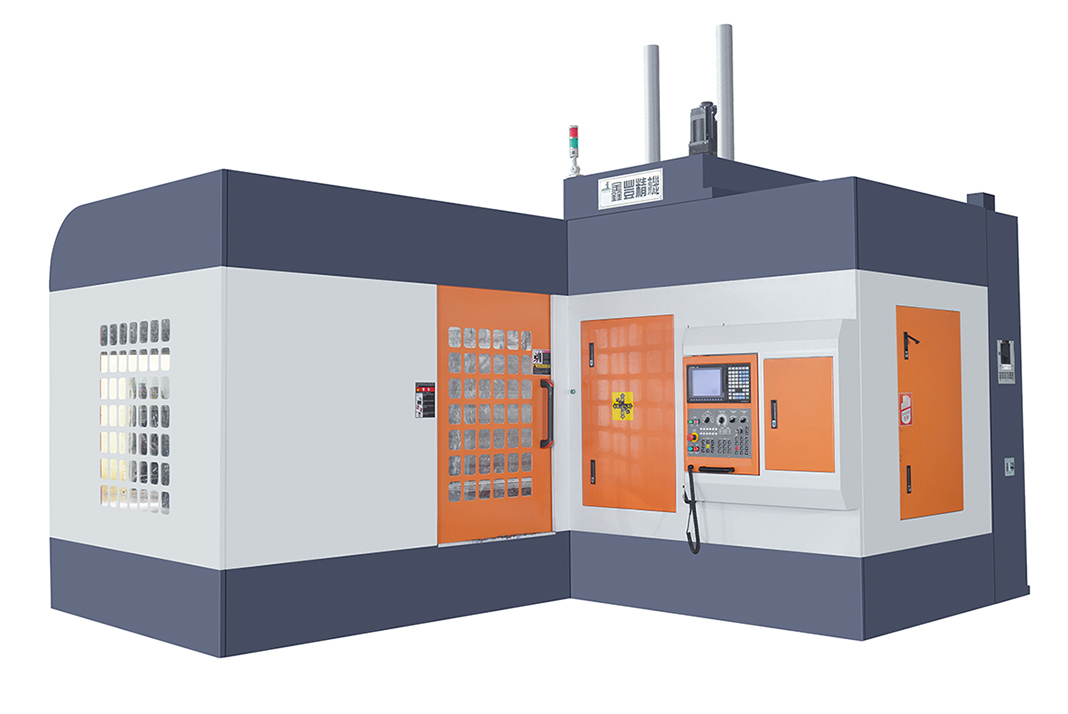

Dongguan Jiashun Automation Machinery Co., Ltd., a Taiwan – joint – venture high – tech enterprise in the manufacturing hub of Dongguan, presents our equipment. Specializing in high – end CNC machine tools, we develop, produce, and sell a range including CNC gantry milling machines, grinders, and machining centers.

Our equipment, like the precision gantry milling machines, boasts high rigidity, precision, efficiency, and cost – effectiveness. Backed by over 20 years of innovation, we’ve secured numerous patents and certifications, ensuring quality. Used in mold manufacturing, aerospace, and more, our machines reflect our “survive by quality, develop by reputation” philosophy. Trust our equipment to power your production—Xinguofeng, your partner for reliable machining solutions.

Processing capacity

Our strong production capabilities enable us to meet all of your project requirements from prototype to production.

On time delivery

We value and understand the importance of on-time delivery, so we will make a suitable production plan for your project.

Excellent experience

Our experts will assist you and respond to your inquiries promptly, bringing you an exceptional customer experience.

Jaeden Higgins

JIASHUN machine tools, born from their robust R&D, have been game-changers for our aerospace parts production. The precision of their gantry milling machines and the reliability of their systems keep our operations seamless. Their focus on quality shines through—definitely a trusted partner we’ll continue to rely on.

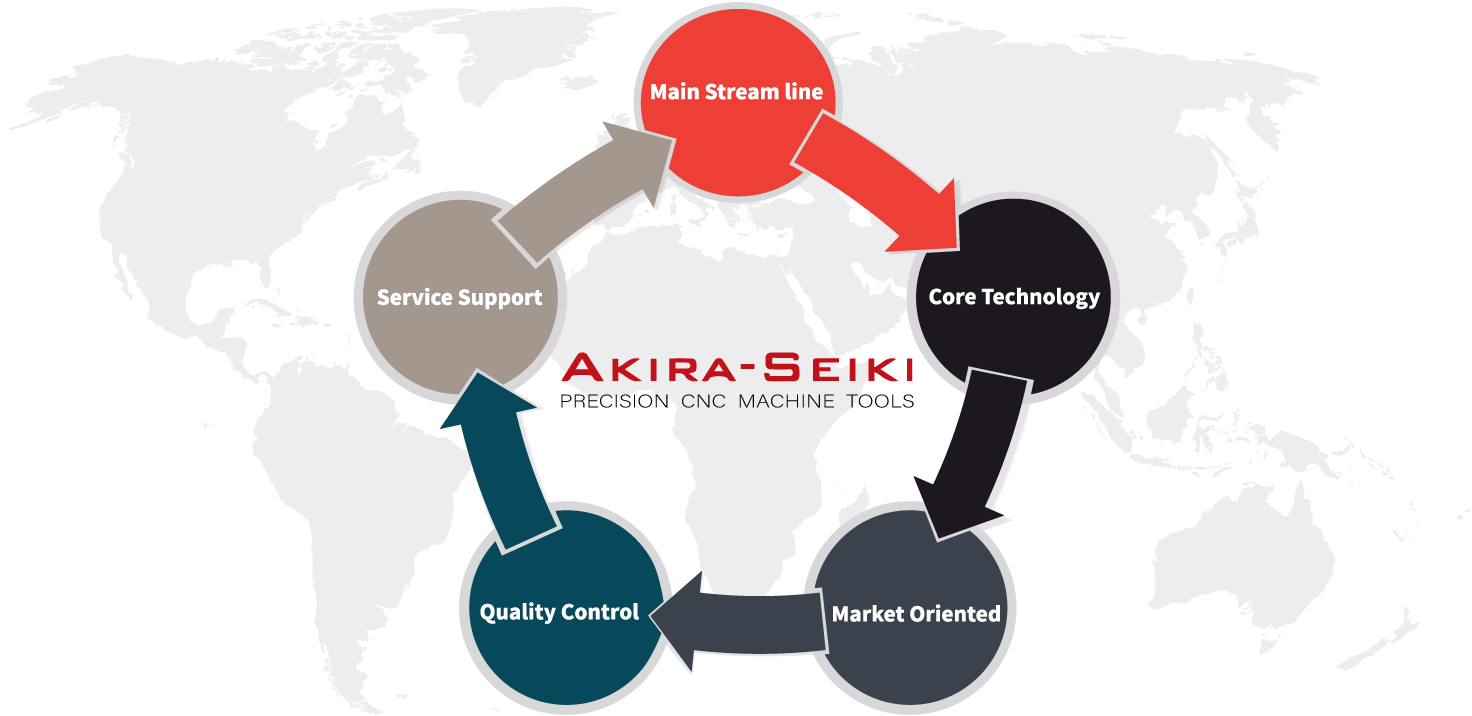

Service Support

24-hour online response & solution is our biggest goal.

Quality Control

- Starting from the design criteria, Jiashun Automation has established Quality Control Resume’, Incoming Inspection, and Outgoing Inspection with a complete SOP, which complies with the ISO9001: 2015 international standard.

JIASHUN Outstanding Base

The outstanding performance of Jiashun Automation products consistently win praise from end users for

their productivity, high accuracy, finishing, quality and user-friendly.

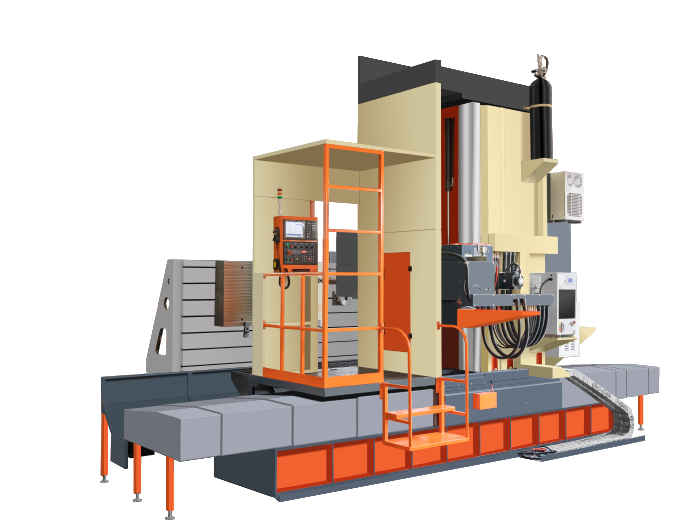

Jiashun Automation Machine

Metal Cutting

Series

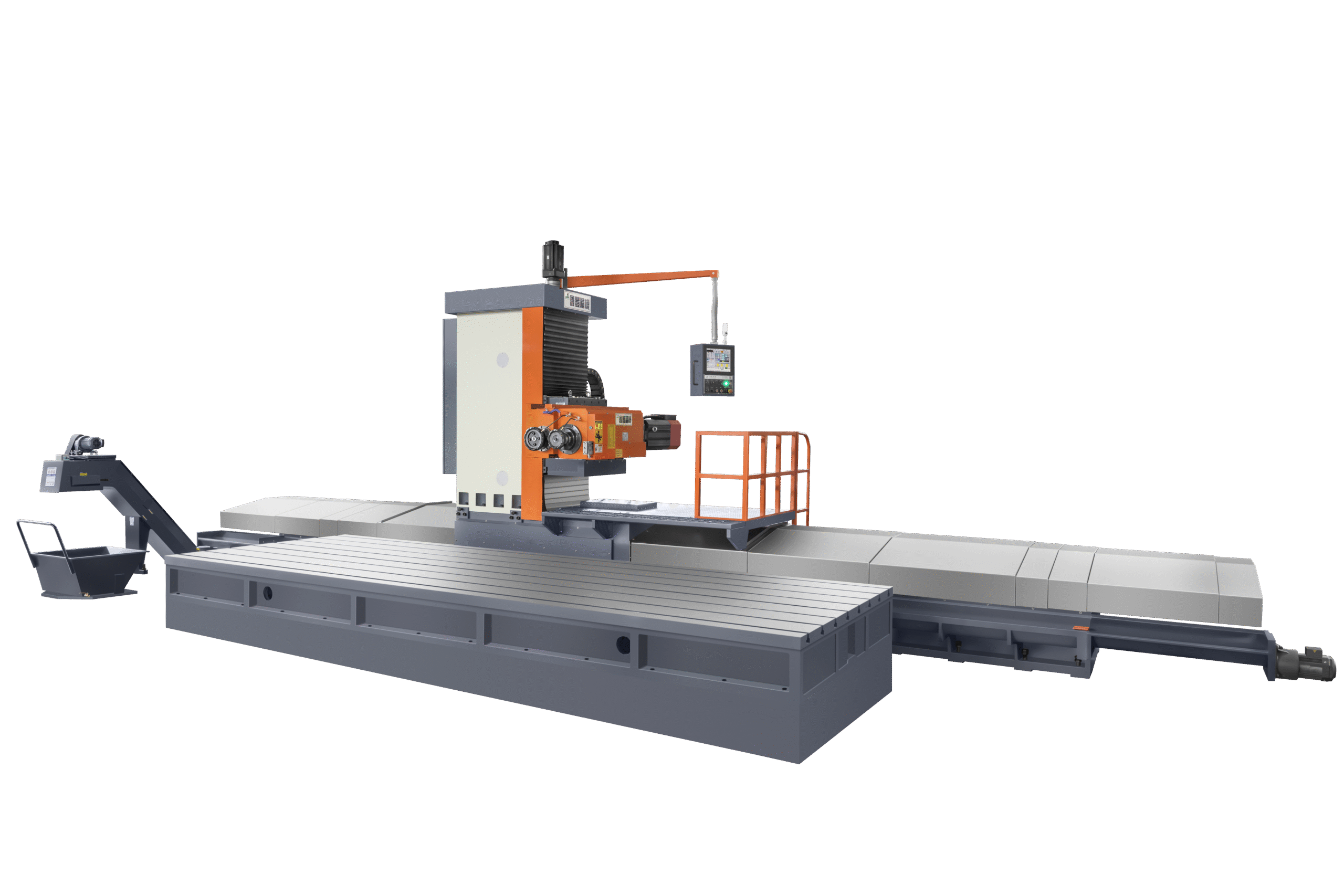

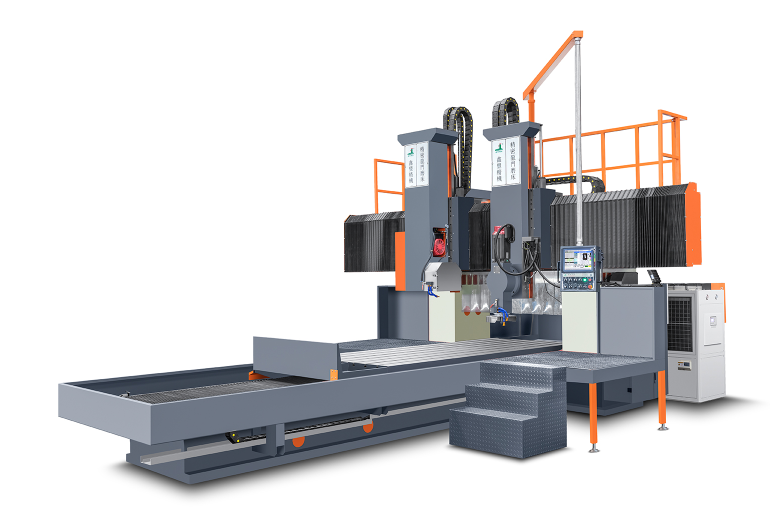

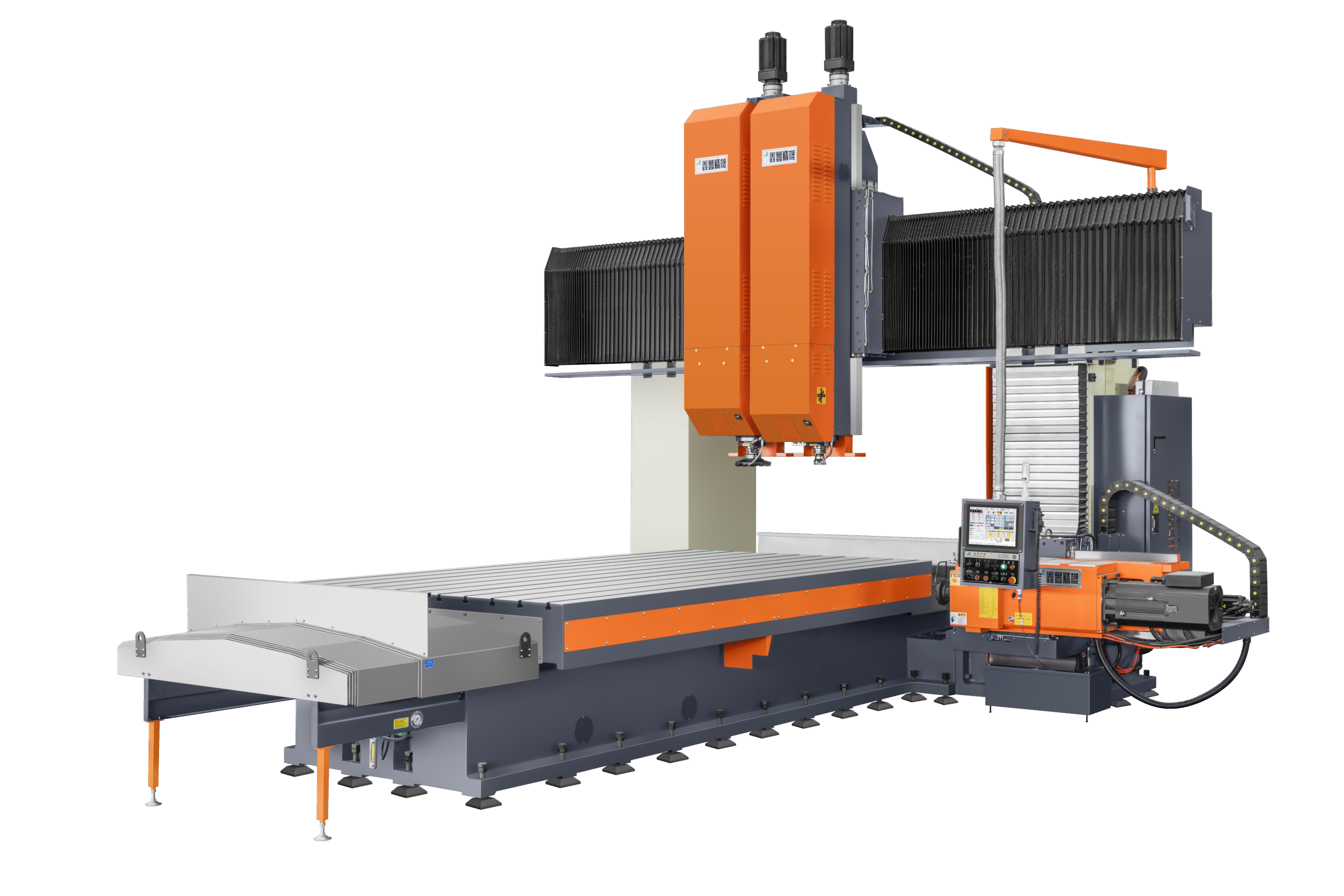

Showcasing Jiashun Automation advanced CNC machine tools—from dual – spindle gantry mills to precision boring – milling machines. High – rigidity, high – precision, built for mold, aerospace & more industrial needs.

▍Excellent and experienced technical talents and reliable technology

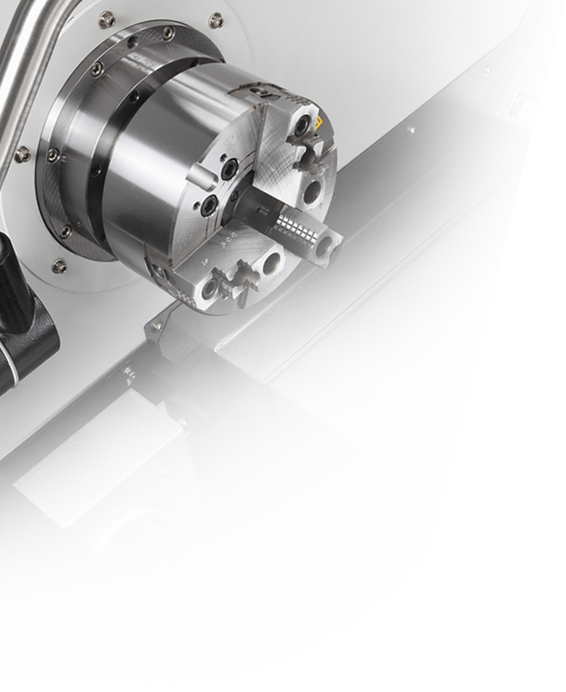

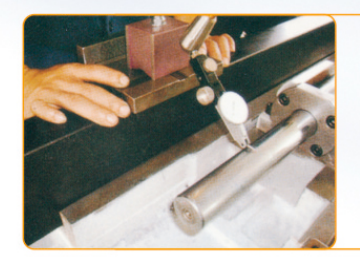

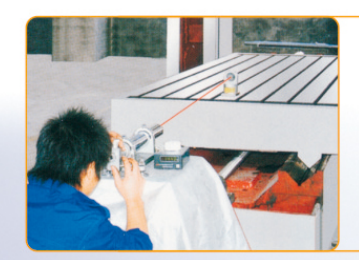

- Triaxial Detection

Precision detection and checkout for triaxial screw capPrecision measuring tools are used for detection andcheckout to quarantee the concentricity of axial directionof our machine tool and keep it running under low loadingcondition.

-Triaxial Scraping

The shaft sliding surface is precision-scratched and the exquisite scraping technology ensures that the machine tool achieves a smooth sliding surface, precise processing accuracy and a solid joint surface.

-Collimator Check

The auto collimator is used for measurement and checkoutand parallelism and perpendicularity of our machine toolsare quaranteed.

- Guideway Hardness

High frequency hardness treatment and check of guidewaysurface guarantee the hardness of guideways, and theservice life of our machine tool is prolonged.

Inquiry & Initial Contact

Reach out with your machining needs. We respond promptly, introducing our expertise in fields like aerospace and new energy equipment manufacturing.

Detailed Needs Discussion

Dive deeper into your requirements—whether for large mold processing or high-speed rail parts. We gather specifics to align solutions.

Custom Solution Design

Craft a tailored plan using our high-precision, rigid metal cuttingmachine tools, ensuring efficiency and cost-effectiveness as per your demands.

Proposal Review & Confirmation

Present the solution for your review. Adjust based on feedback, leveraging our market reputation to finalize details.

Agreement & Execution

Sign the agreement, backed by our ISO and high-tech enterprise certifications. Deliver machines as scheduled with technical support.

Post-Cooperation Support

Provide ongoing service to ensure optimal performance. Your satisfaction drives our pursuit of long-term partnership.

Choose A Reliable Manufacturer

Choose A Reliable Manufacturer

When precision, durability, and trust matter,Jiashun Automation Machinery stands as your steadfast partner. As a Taiwan joint venture high-tech enterprise with over 20 years of expertise, we blend advanced technology with proven excellence in CNC machine tools—engineered for high rigidity, precision, and cost performance.

Customers We Serve

What services can we provide

Short Delivery Time: With a physical factory, we have strong production capacity and sufficient inventory.

Adequate Capacity: We reject false labeling and ensure rated capacity.

Authoritative Certification: Passed various authoritative certifications, meeting international standards.

Customizability: Dimensions, capacity, protection board, and other requirements can be customized according to customer needs.

Quality Assurance: We build a comprehensive quality system from parts to finished products to ensure product quality.

Perfect Service System: We respond quickly to customer questions and provide solutions.

Undertake to order all kinds ofnon-standard machine tools

Precision movingbeam gantryboring and milling machine(20m)